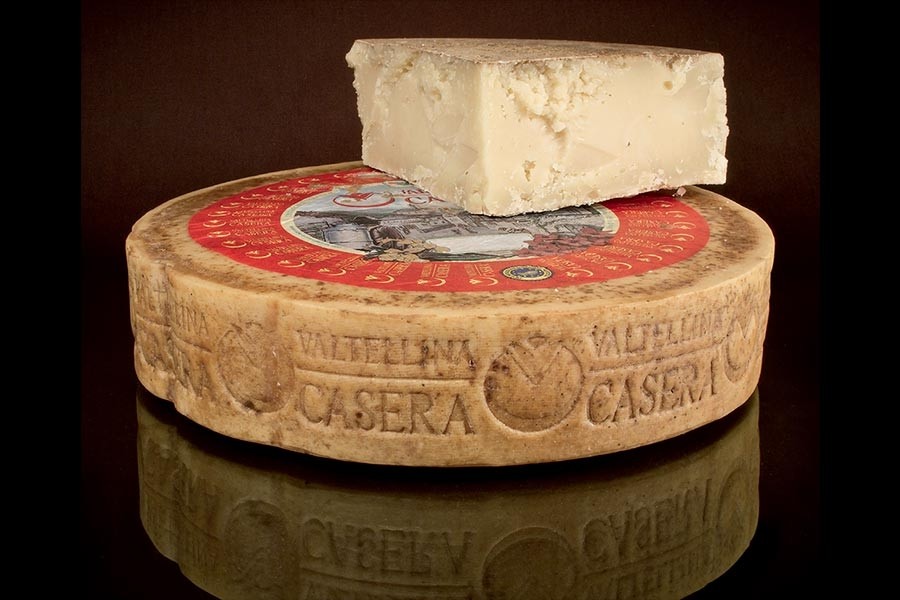

Product description

Valtellina Casera PDO is a cheese produced with semi-skimmed cow’s milk drawn from cows fed mainly on forage from the production area.

Production method

The milk is obtained from two or more milkings and is partially skimmed before curdling, taking advantage of the spontaneous formation of micro-flora.

The curd, obtained through curdling the milk with calf rennet, is cooked for nearly 30 minutes at 40-45°C; it is then broken until the grains are the size of corn kernels.

The extracted mass is placed in traditional molds bearing the mark of origin and it is pressed for 8-12 hours.

Ripening takes place in environments with a temperature of 6-13°C and lasts for at least 70 days; the pieces are then quality-controlled and fire-branded.

IT

IT